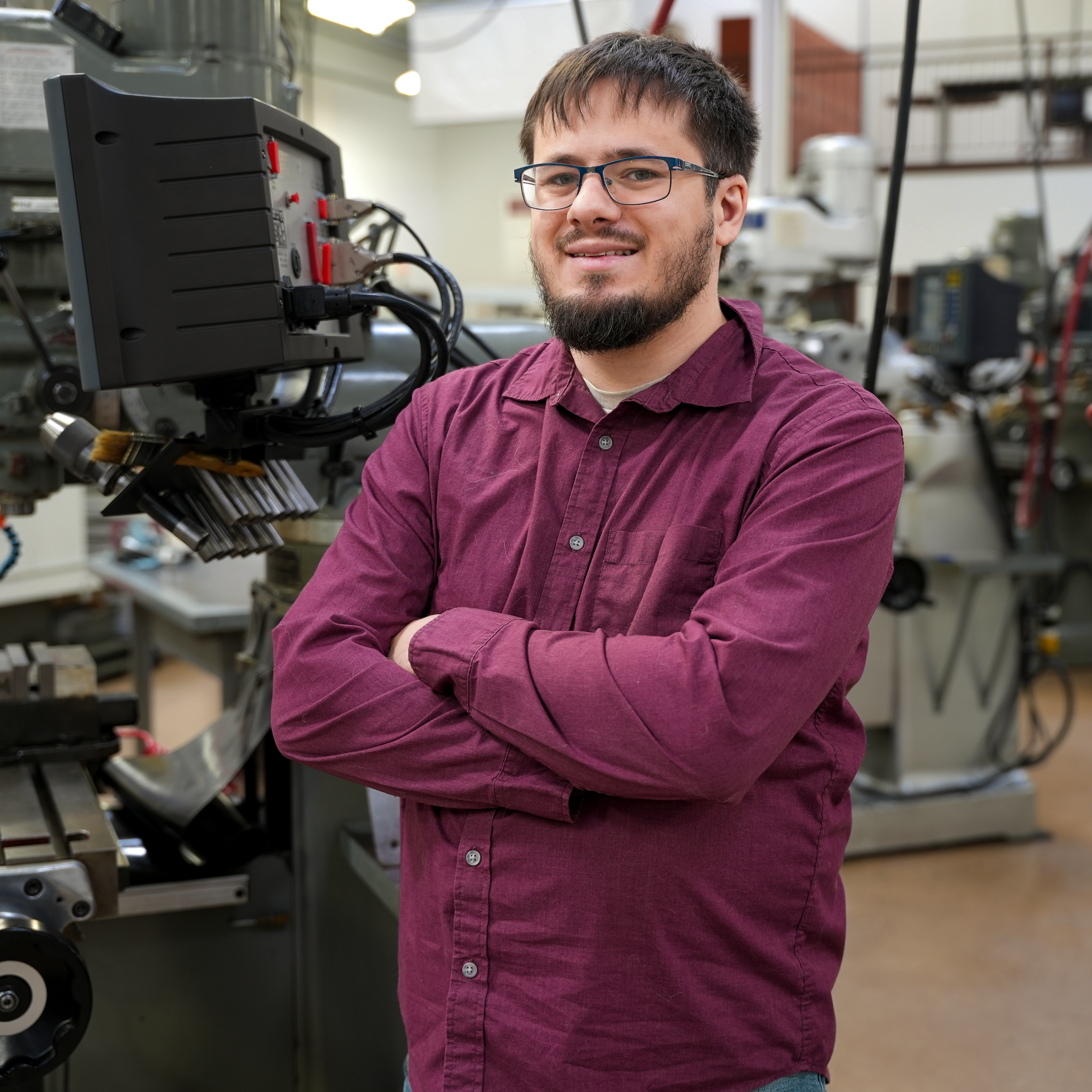

Robert Bach transformed his life at CWI, finding purpose in machining and welding and continuing on in his studies to shape a career he once struggled to imagine.

Read more about Bach Finds His Fit at CWIMachine Tool Technology

Master the Art of Machine Tools and Open Doors to In-Demand Careers

Program Overview

Are you intrigued by precision manufacturing and keen to work with state-of-the-art equipment? The Machine Tool Technology program at College of Western Idaho (CWI) is your gateway to a career in this high-demand industry. Whether you aim for a Basic Technical Certificate, Intermediate Technical Certificate, or an Associate of Applied Science degree, this program equips you with the skills needed for machine tool operation.

Learn to expertly handle engine lathes, milling machines, grinders, and computer numerical control (CNC) machines. Delve into the materials and processes used by the metals manufacturing industry. The program combines classroom instruction with practical experience, ensuring you are well versed in precision measurements and test equipment. You will also solve real-world problems and build connections with leading local employers, setting the stage for a successful career in a variety of industries.

Degree or Certificate Type

Associate of Applied Science

Intermediate Technical Certificate

Basic Technical Certificate

Cost

Additional cost may apply.

Time to Complete

1 – 2 years

Primary Location

Major Exploration

Major Exploration

Are you ready to shape the world with precision and skill? Join us to explore the Machine Tool Technology program at CWI and discover how you can turn your passion for machining into a rewarding career.

Learning Opportunities

- Hands-On Equipment Training: Master the use of essential machine tools in a real-world setting.

- Industry-Relevant Skills: Develop expertise in various materials and manufacturing processes.

- Problem-Solving Experience: Tackle practical challenges, enhancing your readiness for the workplace.

- Career Networking: Build valuable industry connections with local manufacturing and machine shops.

- Diverse Career Paths: Prepare for opportunities across a range of industries that value precision manufacturing skills.

Areas of Study

Degrees & Certificates

Machine Tool Technology – Associate of Applied Science Degree

Cost: $13,193

Machine Tool Technology – Intermediate Technical Certificate

Cost: $10,743

Machine Tool Technology – Basic Technical Certificate

Cost: $6,409

Career Opportunities

Machinists

Set up and operate a variety of machine tools to produce precision parts and instruments out of metal. Includes precision instrument makers who fabricate, modify, or repair mechanical instruments. May also fabricate and modify parts to make or repair machine tools or maintain industrial machines, applying knowledge of mechanics, mathematics, metal properties, layout, and machining procedures.

28

Annual Openings*

$24.12

Hourly Median Wage*

$50,170

Annual Median Salary

11.17%

Growth (2025 – 2035)*

Multiple Machine Tool Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend more than one type of cutting or forming machine tool or robot.

7

Annual Openings*

$20.84

Hourly Median Wage*

$43,347

Annual Median Salary

11.3%

Growth (2025 – 2035)*

Cutting, Punching, and Press Machine Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend machines to saw, cut, shear, slit, punch, crimp, notch, bend, or straighten metal or plastic material.

4

Annual Openings*

$19.94

Hourly Median Wage*

$41,475

Annual Median Salary

16.82%

Growth (2025 – 2035)*

Grinding, Lapping, Polishing, and Buffing Machine Tool Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend grinding and related tools that remove excess material or burrs from surfaces, sharpen edges or corners, or buff, hone, or polish metal or plastic work pieces.

3

Annual Openings*

$18.39

Hourly Median Wage*

$38,251

Annual Median Salary

6.54%

Growth (2025 – 2035)*

Extruding and Drawing Machine Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend machines to extrude or draw thermoplastic or metal materials into tubes, rods, hoses, wire, bars, or structural shapes.

2

Annual Openings*

$18.93

Hourly Median Wage*

$39,374

Annual Median Salary

10.47%

Growth (2025 – 2035)*

Layout Workers, Metal and Plastic

Lay out reference points and dimensions on metal or plastic stock or workpieces, such as sheets, plates, tubes, structural shapes, castings, or machine parts, for further processing. Includes shipfitters.

1

Annual Openings*

$30.45

Hourly Median Wage*

$63,336

Annual Median Salary

1.35%

Growth (2025 – 2035)*

Forging Machine Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend forging machines to taper, shape, or form metal or plastic parts.

N/A

Annual Openings*

$20.33

Hourly Median Wage*

$42,286

Annual Median Salary

N/A

Growth (2025 - 2035)*

Rolling Machine Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend machines to roll steel or plastic forming bends, beads, knurls, rolls, or plate, or to flatten, temper, or reduce gauge of material.

N/A

Annual Openings*

$20.89

Hourly Median Wage*

$43,451

Annual Median Salary

N/A

Growth (2025 - 2035)*

Drilling and Boring Machine Tool Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend drilling machines to drill, bore, ream, mill, or countersink metal or plastic work pieces.

N/A

Annual Openings*

$19.26

Hourly Median Wage*

$40,061

Annual Median Salary

N/A

Growth (2025 - 2035)*

Lathe and Turning Machine Tool Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend lathe and turning machines to turn, bore, thread, form, or face metal or plastic materials, such as wire, rod, or bar stock.

N/A

Annual Openings*

$20.39

Hourly Median Wage*

$42,411

Annual Median Salary

N/A

Growth (2025 - 2035)*

Milling and Planing Machine Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend milling or planing machines to mill, plane, shape, groove, or profile metal or plastic work pieces.

N/A

Annual Openings*

$20.42

Hourly Median Wage*

$42,474

Annual Median Salary

N/A

Growth (2025 - 2035)*

Heat Treating Equipment Setters, Operators, and Tenders, Metal and Plastic

Set up, operate, or tend heating equipment, such as heat-treating furnaces, flame-hardening machines, induction machines, soaking pits, or vacuum equipment to temper, harden, anneal, or heat treat metal or plastic objects.

N/A

Annual Openings*

$23.13

Hourly Median Wage*

$48,110

Annual Median Salary

N/A

Growth (2025 - 2035)*

Metal Workers and Plastic Workers, All Other

All metal workers and plastic workers not listed separately.

N/A

Annual Openings*

$17.92

Hourly Median Wage*

$37,274

Annual Median Salary

N/A

Growth (2025 - 2035)*

*Data sourced from Lightcast™, a labor market analytics tool, and limited to the state of Idaho. Contact CWI Institutional Research for questions regarding this data. Career pathways may require further education beyond CWI.

Testimonial Carousel

Admissions

Step 1

- Apply to CWI.

- Choose Machine Tool Technology as your major.

Step 2

- Complete the Free Application for Federal Student Aid (FAFSA).

Cost & Aid

As a student in this program, you may be eligible for financial aid and scholarships.

Enrichment Opportunities

Enhance your academic experience, expand your knowledge, reach your goals, and celebrate your achievements.

Advising

Already a student? We are here to help you navigate your educational journey, connect you to academic and support resources, and achieve your academic or career goals.

Transfer Information

Plan ahead for a smooth transition to a four-year college or university.

Clubs

College of Western Idaho is proud to compete in SkillsUSA, a nationwide organization seeking to improve the quality of our nation's future skilled workforce through personal, workplace, and technical skills training.

News

College of Western Idaho’s CTE Summer Bridge Program welcomed 22 high school juniors for a week of hands-on learning, industry exploration, and college preparation across skilled trades and...

Read more about Summer Bridge Sparks Passion for Skilled Trades and TechnologyThe Nagel Foundation scholarship empowers second-year career and technical education students to complete their education.

Read more about 7 Years: Nagel Foundation Continues Support for CWI StudentsReagan Heffelfinger’s journey to becoming a machinist at College of Western Idaho was shaped by resilience, overcoming health challenges and career detours to discover her passion for machining...

Read more about Shaping Metal, Defying Odds: A CWI Graduate’s Path to SuccessJuniors from area high schools experienced hands-on instruction and explored career paths during the CWI Summer CTE Bridge Program.

Read more about High School Juniors Cross Off Skills at CWI Summer CTE Bridge ProgramAfter a $224,000 donation on April 8, The Nagel Foundation has now invested over $1M to support successful student outcomes at CWI.

Read more about Nagel Foundation Scholarship Fund Tops $1M in Donations After 6 Years Supporting CWI StudentsThe College of Western Idaho Foundation recently received an $18,000 grant from the Gene Haas Foundation that will support the College’s Machine Tool Technology Program.

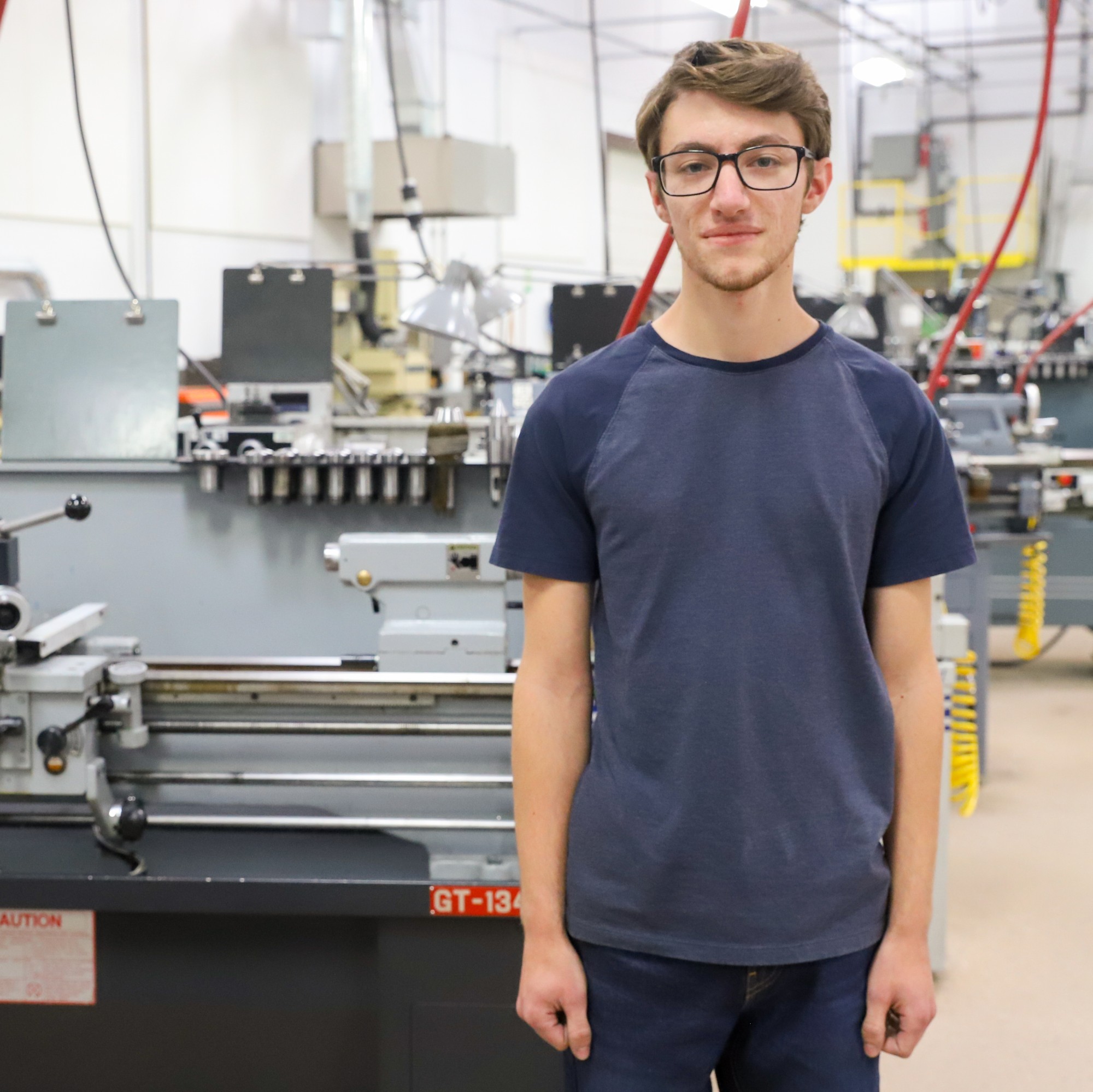

Read more about Machine Tool Technology Receives 18K from Gene Haas FoundationIn his fourth year at College of Western Idaho, Machine Tool Technology student, Wade Kindberg, continues to learn new skills and trades for a future career.

Read more about Finding His True Calling through College of Western IdahoNew scholarship honors late CWI Machine Tool Technology graduate, Nathaniel Stewart Dando.

Read more about Dando 300 Scholarship Honors Late CWI StudentThe Nagel Foundation scholarship empowers second-year career and technical education students to complete their education.

Read more about Nagel Foundation Continues Commitment to StudentsCongratulations to Bradley Dougal, a 2019-2020 Nagel Foundation scholarship recipient.

Read more about Education Sparks FutureBiology instructor, Dusty Perkins, Biology Club, and Machine Tool Technology Program to host a native bee habitat building during Connections Project.

Read more about Connections Project to Feature Native Bee Habitat ProjectRequest More Information

Interested in learning more about this program or getting started? Fill out the information below to be contacted by a member of our team.

Connect With Us

Ready to get started? Our team looks forward to assisting you!