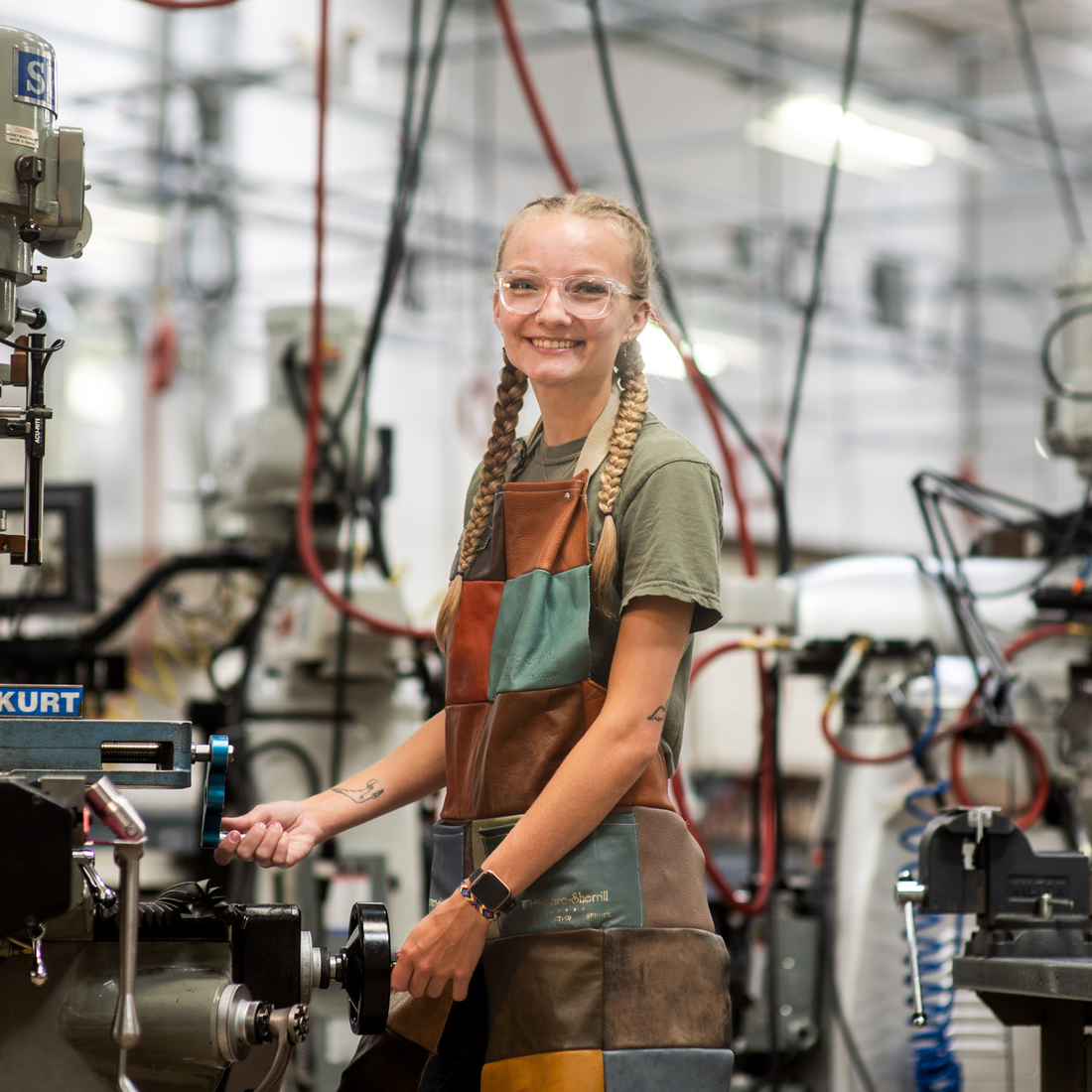

Reagan Heffelfinger is no stranger to metal. A recent graduate of College of Western Idaho’s (CWI) Machine Tool Technology program, Heffelfinger began working with her dad on his Volkswagen as a 3-year-old. By the time she was 16, she was performing regular maintenance on her own car.

Her road to becoming a machinist — the same trade as the storied Rosie the Riveter of World War II fame — may seem like it would have been a straightforward one. However, Heffelfinger’s path, full of roadblocks and detours, has been representative of a common experience for many students at CWI where “traditional” fully embraces the untraditional.

A Heartbreaking Discovery

In high school, Heffelfinger began experiencing troublesome symptoms more common to adults twice her age, including shortness of breath, a racing heartbeat, and dizziness. Traumatically, she found herself going from cardiologist to emergency room to heart surgery, all within the span of three months. “That year was hard. I went from what I thought was healthy to having three heart conditions, two of which are chronic.”

Forks in the Road

After graduating high school during the pandemic, Heffelfinger enrolled at Arizona State University to study mechanical engineering online, but she quickly realized that a four-year degree wasn’t a good fit.

She then enrolled in CWI to study health sciences, with the goal of becoming a nurse. However, as she waded through microbiology and similar courses, she again understood that this career path wasn’t for her.

Heffelfinger’s dad, always her biggest supporter, gently nudged her to explore machining and reminded her that her uncle had been a machinist in the Navy. After more research, she eagerly joined the two-year Machine Tool Technology program at CWI.

“It just clicked”

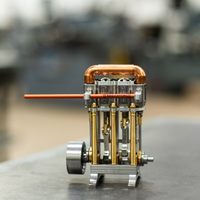

In the first year of the program, students go from learning the fundamentals of machining to manually crafting a small-scale working motor. Once again, however, Heffelfinger’s health presented her with complications by making attendance difficult and causing her to fall behind. Despite these limitations, CWI’s uniquely supportive culture — exemplified by encouragement from her instructors and classmates — helped Reagan complete her first year.

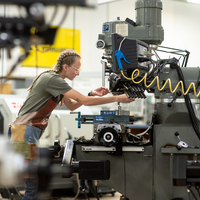

Things began looking up in year two as students learned how to program and use machines for cutting. “Once I learned how to talk to and use the machine, it was a night and day difference. I saw that I actually could make an engine, and I did.”

Shaped by Metal

“When I first started the Machine Tool program, all I saw were blocks of super hard metal, and I had no idea how to go about making anything. Toward the end of my second year, I was able to look at a bar stock and know exactly how to make the parts I needed,” she said reminiscing. “I knew how to face it and how to cut it and how to machine it.”

When she started the program, Heffelfinger’s dad and grandfather made her a leather apron made of different colored squares. It became a source of pride and reflective of her untraditional experience becoming a journeyman machinist. Looking back, Reagan recalls that “this road has made me more durable and resilient as a person because metal doesn’t want to be carved. My job is to make it into something beautiful or something useful, and I’m good at it.”

Master machine tooling and turn your passion for precision into a career through our Machine Tool Technology program.